Aging and preparing the tops:

These tops are stickered and ready to go in the oven. I have previously used so-called “Thermowood”, which is heated in a vacuum and has a significant resilience against humidity changes. Also, my Montreal-based colleague Jeremy Clark told me how he bakes some of his tops in the oven. So instead of buying Thermowood from Europe, I decided to try to make my own and speed up the aging process in the kitchen.

In order to let the evaporating humidity escape, the oven door can be kept slightly open – just like when you make jerky. The temperature used here was around 100 degrees Celsius (or 200 F). Baking time in this case was short, just one hour. In the future I would like to try something like 6-8 hours.

The tops are baked and ready for joining. There is a little bit of a burn on the bottom right corner, since I had a classic misunderstanding of an immigrant – I put the heat to 200 Celsius instead of Fahrenheit. But once I had smoke in the kitchen, I realized my mistake and turned it down…

The next step in the process will be measurements of weight and stiffness. I have measured all tops before the baking, and now I want to accumulate data on what impact this process has on the weight/stiffness characteristics of this wood.

Measuring stiffness and weight:

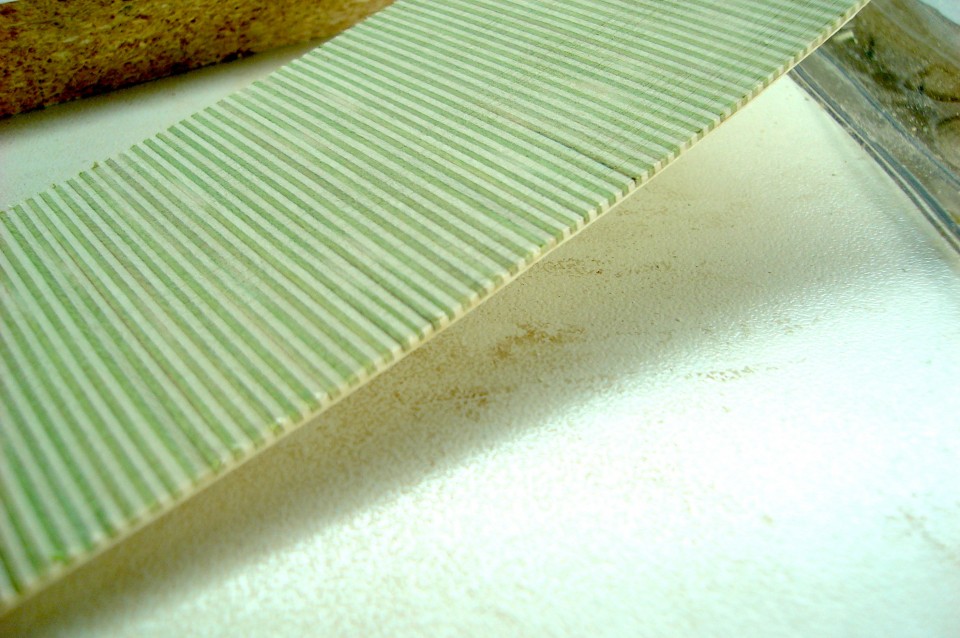

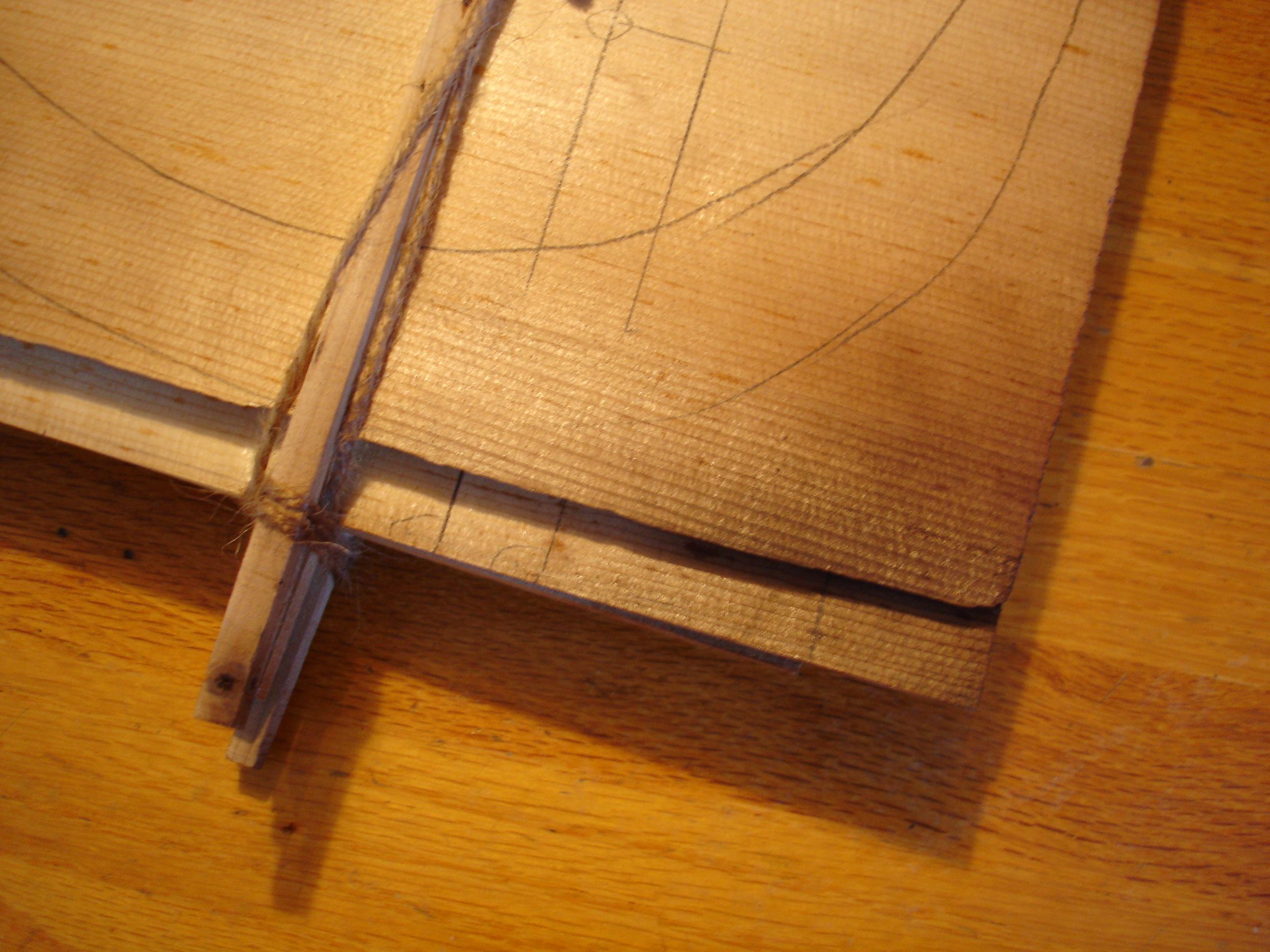

Here is my setup of stiffness measurement. It is based on the drawings (fig. 30) that were published in 1977 in the Bulletin du Groupe d’ Acoustique Musicale by the authors Daniel Friedrich and Emile Leipp. In the case of the tops measured here, the stiffness after baking was not significantly increased or sometimes even slightly decreased. The weight of the tops decreased by about 5%, indicating that the ratio of stiffness to weight was improved. I would recommend more measurements and experimentation to find out whether baking the tops can actually have a detrimental effect on the stiffness of a spruce top. In regards to aging, these detrimental effects must not necessarily be negative. If the baked spruce top would have decreased in stiffness over time anyways, one could conclude that the reduced stiffness due to heat treatment is indeed an effective method of aging or tempering the top.

By the way – if any luthiers are interested in collectively gathering data on spruce top deflection, let me know. I can document more details of my setup here so that a common measurement setup can be established and data from luthiers around the world can be collected and evaluated. I imagine a large pool of data could permit us to establish standardized stiffness ratings that could be beneficial to our trade. If it hasn’t been done already.